https://www.link2pump.com/wp-content/uploads/2023/09/SurveyShowsCarriersRemainOptimisticAboutDemand.jpg

682

1022

Nate Riggins

/wp-content/uploads/2023/08/Logo-Colors.png

Nate Riggins2022-09-12 13:03:222025-07-09 13:32:31Survey shows carriers remain optimistic about demand

https://www.link2pump.com/wp-content/uploads/2023/09/SurveyShowsCarriersRemainOptimisticAboutDemand.jpg

682

1022

Nate Riggins

/wp-content/uploads/2023/08/Logo-Colors.png

Nate Riggins2022-09-12 13:03:222025-07-09 13:32:31Survey shows carriers remain optimistic about demand https://www.link2pump.com/wp-content/uploads/2023/09/SurveyShowsCarriersRemainOptimisticAboutDemand.jpg

682

1022

Nate Riggins

/wp-content/uploads/2023/08/Logo-Colors.png

Nate Riggins2022-09-12 13:03:222025-07-09 13:32:31Survey shows carriers remain optimistic about demand

https://www.link2pump.com/wp-content/uploads/2023/09/SurveyShowsCarriersRemainOptimisticAboutDemand.jpg

682

1022

Nate Riggins

/wp-content/uploads/2023/08/Logo-Colors.png

Nate Riggins2022-09-12 13:03:222025-07-09 13:32:31Survey shows carriers remain optimistic about demand

Electric vehicle demand – has the world got enough lithium?

Fleet ManagementThe demand for electric vehicles (EVs) is rapidly increasing, but is there enough lithium to power all of them?

Common causes of semi-truck breakdowns

Fleet ManagementDon't let breakdowns derail your journey! Stay prepared by knowing the common causes of semi-truck breakdowns.

How to improve fleet productivity with telematics

Fleet ManagementAccording to a recent survey, companies that have implemented telematics have seen a 21% decrease in accident costs.

How technology can impact truck drivers

Fleet ManagementTechnology is revolutionizing the trucking industry, bringing numerous benefits to truck drivers and fleet management.

Find ways to improve efficiency and cash flow in your fleet

Fleet ManagementAre you looking to increase efficiency and cash flow in your fleet? Take a look at these tips.

Logistics resolutions for 2022

Fleet ManagementAs we bid farewell to 2021, it's important to evaluate what worked and what didn't in the past year.

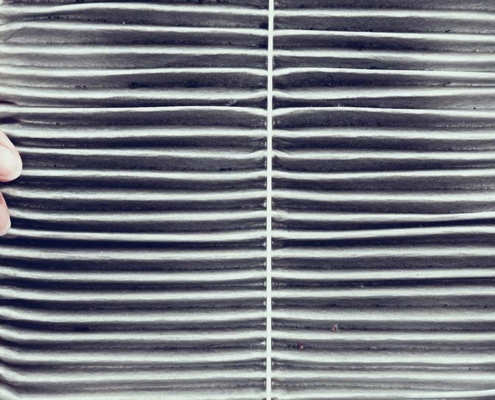

Clean air filter: reduction in fuel consumption

Fleet ManagementCleaning and changing air filters regularly can make a real difference in your fuel costs. Learn some benefits of changing your air filter regularly.

Fuel Management System Market to rise at CAGR of 8.9% through 2030

Fleet ManagementTracking fuel expenses can be a hassle, but not anymore! Introducing Link2Pump, the solution you've been waiting for.

Trends for Fleet Maintenance Management

Fleet ManagementManaging a fleet is not an easy task, but with the right tools and strategies, it can be a smooth ride!

Link2Pump offers fuel management systems that allow business to move from the clipboard to the cloud.